Vertical integration is the foundation that allows us to dream, design, and execute without limits.

Wood Processing

DROMEAS operates a state-of-the-art wood processing unit, equipped with the latest-generation machinery from the world’s leading manufacturers.

The production process includes:

-

Cutting of surfaces into various shapes and dimensions.

This stage includes a raw material cutting machine, centrally controlled by the production management computer, with optimization capabilities based on inventory levels and current production orders. -

Edge finishing of panels

-

Surface lamination with HPL, PVC, or veneer.

Two high-capacity edge banding machines operate per shift, while two specialized processing centers handle curved surface edging in large quantities. -

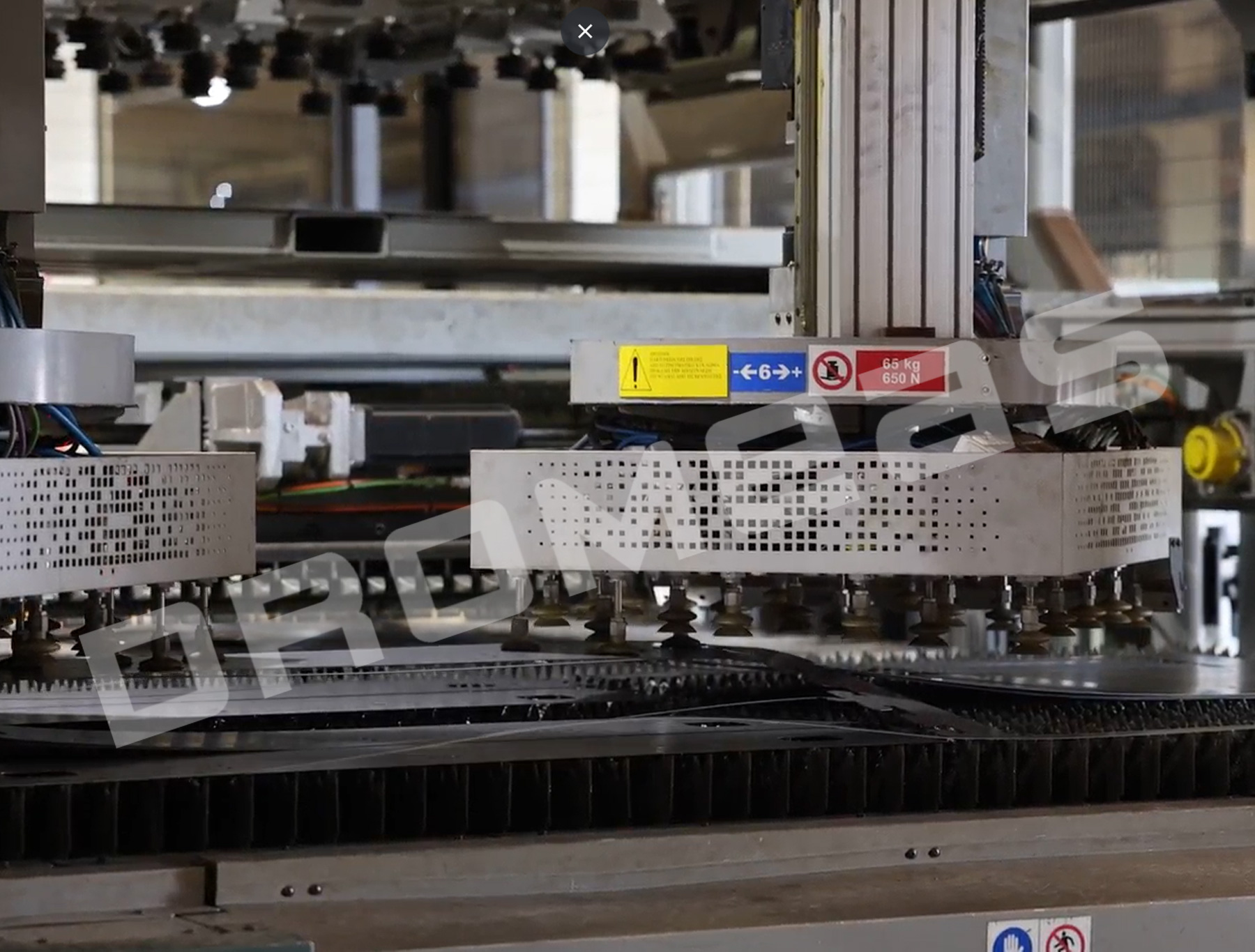

Precision drilling

-

Surface painting with lacquer or varnish

For wood and glass surfaces, an automated coating and drying system is used, featuring climate control and infrared technology — enabling high productivity per shift. -

Final inspection and packaging of parts

All of the above processing stages are electronically controlled, ensuring full repeatability and consistent production quality. The factory’s productivity in fully processed melamine-coated products — including cutting, edge finishing, and drilling — reaches 130 m³ of raw material, equivalent to 5,000–6,000 office desk surfaces per 8-hour shift.

Equally high productivity is achieved in the lacquer painting department as well as in the final inspection and packaging section.

Metal Processing

DROMEAS operates a state-of-the-art steel and aluminum processing unit.

The steel processing department is equipped with advanced machinery for cutting, drilling, forming, and welding of steel surfaces, tubes, and various profiles.

Cutting and drilling operations are carried out using latest-generation LASER machines, as well as electronically controlled shearing systems.

Forming is performed either by electronically guided machines or with high-pressure forming molds.

Tube forming is executed by a fully automated five-axis robotic machine, ensuring maximum precision.

Welding is conducted using high-precision robotic systems that guarantee top-quality joins.

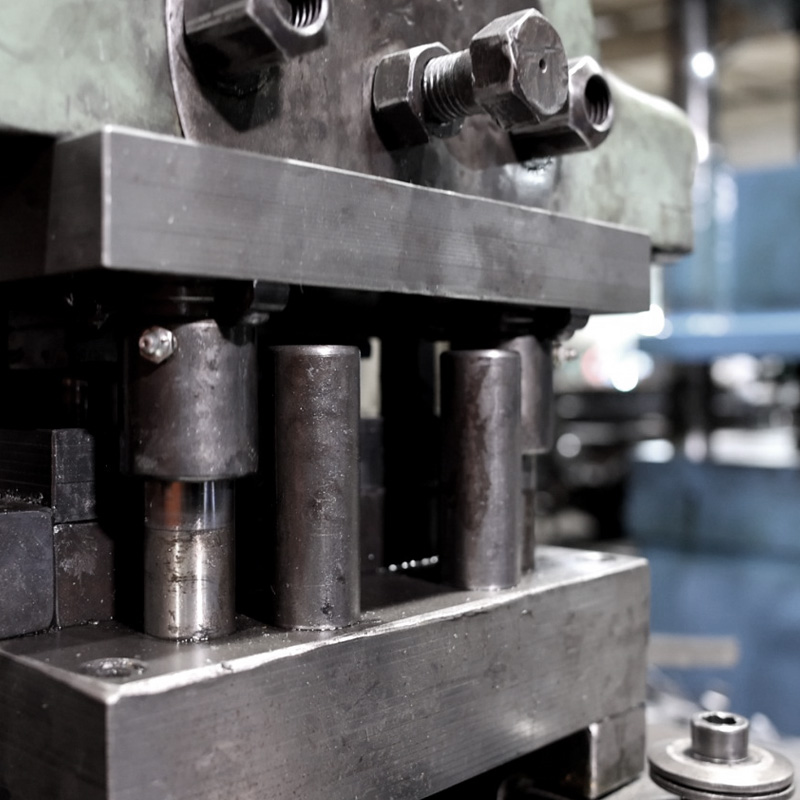

The steel processing unit also produces custom lathe-turned micro-components, used in the assembly of various chair mechanisms and other furniture parts.

Aluminum Casting

The aluminum casting unit is equipped with cutting-edge machinery.

Aluminum casting is performed in both liquid and semisolid (SEMISOLID) form in special high-pressure molds, at 700 °C ±20, while ZAMAC casting is carried out at 420 °C.

All casting parameters are electronically controlled to ensure consistent quality in the finished components.

Semisolid casting (SEMISOLID) is a next-generation process that significantly increases the fatigue resistance of the final product — reaching levels comparable to steel.

The method is based on altering the internal molecular structure of aluminum. To preserve this altered structure without reverting to its natural state, the material must be cast in semisolid form.

This highly specialized process is applied when we aim to replace heavy steel parts with lightweight aluminum components that offer the same level of strength — a technique widely used in the automotive industry to reduce vehicle weight while maintaining mechanical durability.

After casting, the parts undergo machining, sandblasting, drilling, and washing.

The unit also features a robotic surface polishing section for aluminum components, delivering exceptional finish quality.

In addition, the casting facility is equipped with a fully integrated quality control laboratory, which includes:

A. Raw material composition analysis

B. X-ray inspection of the internal structure of components

C. Full and precise dimensional measurement of parts

Plastic and Polyurethane

Plastic Component Molding

Plastic components are produced using injection molding machines and specialized molds.

To ensure high-quality production, DROMEAS operates seven state-of-the-art injection machines of various sizes, with full control over all process parameters during molding.

The raw materials used for plastic parts cover a wide range of technical and mechanical properties, depending on the application of each component, and are always selected with recyclability as a top priority to support environmental protection.

Polyurethane Molding

Polyurethane components are also produced via injection molding in dedicated molds.

DROMEAS uses cast high-density polyurethane foam (>50 kg/m³) for seating upholstery to ensure long-lasting elasticity and durability, delivering maximum comfort and user satisfaction over time.

The polyurethane section also manufactures semi-rigid polyurethane parts, such as armrests for various chair models, using the same molding process.

This department is equipped with four injection molding machines of different capacities.

Upholstery

At the Upholstery and Chair Assembly Unit, upholstery is stitched, fitted, and inspected in detail by experienced and highly skilled craftsmen.

This department is also responsible for the assembly of all individual components, which are entirely produced in-house across DROMEAS’ various production units.

Before packaging and shipping, each chair undergoes a thorough final quality inspection, carried out by trained and experienced personnel.

Mold manufacturing K.E.M

K.E.M. S.A., a 90% subsidiary of DROMEAS, operates its own state-of-the-art facilities in the Serres Industrial Zone (B.I.PE) for the production of metal molds and components across all categories.

Its high-tech and fully equipped machinery enables the manufacturing of injection, punching, and forming molds and parts, meeting the highest quality standards.

K.E.M. S.A. is of strategic importance to DROMEAS, as it significantly accelerates the development and creation of new products. This is achieved through its in-house capabilities to design and manufacture new components and molds, in close collaboration with DROMEAS’ Design & Development Department.

For more information, please visit the company’s website here.

Logistics

The company operates a privately owned distribution center in the commercial zone of Aspropyrgos, near Attiki Odos and the Aspropyrgos interchange.

The facility covers an area of approximately 5,000 square meters and includes 7 loading/unloading bays.

It functions as a fully computerized warehouse, where all incoming and outgoing goods are monitored using the latest digital systems.

The Aspropyrgos warehouse serves the needs of customers in the Attica region.

The distribution center also hosts specialized technical personnel based in Athens, including assemblers, metalworkers, transport drivers, and other key professionals.

Research and Development

Research and Development

We invest in cutting-edge technologies, aiming to achieve a balanced combination of high aesthetics, ergonomics, quality, and cost-efficiency.